Exclusive: Swiss machinery firm Trikno’s chocolate tempering world first

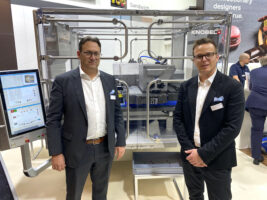

Trkno's stand at the recent ProSweets event. Pic: Neill Barston

A major technology breakthrough from Swiss firm Trikno has recently been exhibited at the ProSweets event, with its tempered nozzle technology (TNT) claiming a global first in delivering ‘just-in-time’ chocolate tempering, as Neill Barston discovers speaking to its CEO, Marc Fuchs.

There’s a genuine sense of excitement as an audience gathers around the Trikno stand at ProSweets, as it boldly displays what it believes is a genuine world first piece of technology.

The company’s recently installed CEO, Marc Fuchs, enthusiastically starts up the prototype tempered nozzle technology (TNT for short) machinery, which promises plenty of potential for the global chocolate processing market.

Its star feature comes in the form of what the Swiss firm’s leader explains as ‘just-in- time’ tempering, which occurs directly on the print head as it supplies the moulds. As he notes this is the real game-changer in its view, and it certainly appears to pique the interest of the many visitors hovering around the booth, to gain a glimpse of the company’s fresh innovations.

It’s on an ambitious mission to carry forward the well-established Knobel machinery, which unfortunately fell into administration in the summer of 2022, amid challenging external conditions as the world struggled to draw clear of a highly- testing pandemic.

However, as the Trikno team explains, acquiring the business in the autumn of that year, including keeping on dozens of its staff, the much-respected company continues to gain a fresh purpose under new ownership.

For many external observers, it appears there’s plenty of interest in the fact that Knobel’s well-regarded name lives on in the entrepreneurial hands of a business that recognises Swiss quality. The new enterprise’s sense of vision is certainly ambitious, with its mission statement asserting ‘it’s not enough that the world associates Switzerland with high quality confectionery – we have the ambition on an international level that Trikno becomes synonymous with the most efficient and innovative ways of making products,” explains the business, as it lays out its plans.

According to the company’s CEO, its latest TNT innovation is indeed catching the eye of potential investors, on a number of levels, against a backdrop of continued buoyancy in machinery sales, despite wider supply chain challenges in the market.

As the firm explains, its solution is based upon a scalable and temperable 3D print head, featuring a specially devised extruder unit, targeting ultra-fine machine decorations and labelling of products with maximum repeat accuracy. Notably, this key new unit makes it possible to create three-dimensional structures with chocolate tempered directly in the nozzles, comparable to a 3D printer. The number of extruder nozzles can be adjusted as required, allowing a high degree of flexibility and adaptability to a wide range of production requirements.

Furthermore, its just-in-time tempering ensures precise control of the chocolate consistency and enables unprecedented fineness and detail in the decoration. By continuously dispensing tempered chocolate with uniform pressure, extremely fine, repeatable lines and dots can now be created by machine. This innovative solution supports the realisation of creative chocolate ideas that were previously difficult to implement by machine.

In addition, direct tempering of the extruder nozzle unit in the 3D print head leads to immediate and distortion- free control over the temperature of the chocolate and can therefore increase the quality of the decorations. According to the company, the processing of chocolate in this manner also effectively reduces the energy required for tempering, which is a key consideration for its sustainability credentials.

Speaking to Confectionery Production at ProSweets, CEO Marc Fuchs (right of pic), explains there had been a positive response at the show for its breakthrough innovation, stating that the ‘sky is open’ in terms of its potential for both smaller artisan and larger scale confectionery manufacturing operations.

He says: “This is our proof of concept, and our next step is to develop a prototype machine, and define the number of print heads for it, and bring the machine to a customer application, collect feedback and then optimise it from there. We’re here to find a customer who is willing to go to the next step with us.

“We’re showing the TNT to demonstrate that the chocolate is properly tempered, and have been making a lot of measurements, and have done a lot of lab trials to show that things like its positioning and speed are good. Our mission is to collaborate with customers and develop together. We’ve already had some enquiries about TNT here at ProSweets, so I think we’ll be busy, which is great,” enthuses Fuchs. He explains one of the most dynamic features of its new line is in its sheer flexibility, and the potential energy saving capabilities are among its standout core strengths.

Strong industry background

As he notes, having come from a background working for major equipment and solutions businesses including many years with Bühler, notably at the company’s impressive Swiss headquarters in Uzwil, he reveals that taking on a new role leading Trikno forward offers an especially energising challenge. Moreover, as he adds, the company, which is located in Felben-Wellhausen, employs 60 people within Switzerland, had already made significant investments into the TNT system’s initial research and development.

Displaying a commendable level of belief in the project, he feels it is likely to have a notable impact in the market, though his team is by no means being complacent in its approach.

As its CEO observes, the company is aiming to have its first fully operational new tempering machine out with a customer later this year.

“Luckily, I had some time to look into the business beforehand, so I officially started in October last year, so it’s been four months in the role. I saw the potential of these beautiful high-tech machines, and when I spoke to customers, I saw the sparks in their eyes, they knew exactly how great they are and what they bring to their production and their business.

“I am just proud to show to the industry that we are back supporting companies again and the feedback we’ve had has been fantastic,” explains the Swiss national, who says there’s a depth of expertise within its ranks which will make difference.

Reflecting further on the TNT’s development, he notes that there are a number of strings to its bow, and he will be keen to explore commercial opportunities in the coming months and years ahead.

Which is precisely why, he says, being seen at shows such as ProSweets is particularly important as it attempts to establish a foothold in what is an undoubtedly competitive international machinery market.

“We came up with the tempering technology as we believe we are the market leader when it comes to decoration, from tiny dots, through to precise different colours and high production.

“However, our existing technology previously had limitations when it came to ultra-fine lines and dots, so we needed to take that technology to the next level, and worked on the extrusion as well as tempering processes. So it’s an all-one solution, which is why we call it the temperance nozzle technology.”

Turning his attention to its other areas of focus, he explains that the business is also continuing competencies in one-shot depositing, as well as cold press technology for hollow figures, plus other fresh chocolate processing systems.

In addition, he also enthuses that the business has developed systems for processing inclusions at a rate of up to 45 per cent of the quantity of a product, representing a considerable improvement on previous achievements.

Decisive show

For his part, Bart Klinkenberg, chief sales officer for Trikno, adds that ProSweets is proving a rewarding experience. While he notes the volumes of visitors may not be quite what they were pre-pandemic, the chance to meet a wide range of potential customers is of significant importance. He says: “It’s been positive here.

“The good thing is that we are been presenting something new, and really unique in the market. So, we have presented ourselves as an innovative company, rather than one that follows others,” he notes, conceding that while it was a relatively late decision to exhibit its TNT system at the show, it is worthwhile in doing so.

He adds: “The ‘just-in-time’ tempering of the machine is a good thing, and also energy consumption-wise it has another positive. We have made it a lot easier for operators to handle, as you don’t need to have an someone operating it who understands all the aspects of depositing and tempering for them to able to use it,” says the chief sales officer, who asserts this is set to prove a decisive factor in terms of delivering precise automated equipment. He notes that it offers advanced in its performance, yet is comparatively manageable to put in place and run within a manufacturing facility.

As for the company’s CEO, he concludes that he is buoyed by the prospect of driving forward the business, and he’s fully welcoming the tests ahead.

Thankfully, its TNT system clearly delivers an innovation focal point and confidence boost, amid the wider industry faces some ongoing challenges in terms of wider market uncertainties.

“The past year or two for the business has been about talking to customers and explaining our situation, and building trust with them. So, this year, we have to bring in the orders, we’ve put a lot of work into it all, and it’s time to harvest now.

“We are very positive and optimistic that we will really be back at the level that customers used to know the business in the good times,” explains the CEO, who says that the business is continuing to export globally.

“The exhibition overall was a success for us. We had a lot of good discussions and feedback around our TNT technology and we had the chance to talk to existing, but also a lot of potential new customers. So, I am very happy about the outcome and I am looking forward to the next year show to present our newest developments.”