Gerhard Schubert targets sustainable packaging systems for ProSweets

Gerhard Schubert is gearing up for a core focus on delivering sustainable packaging solutions for confectionery, including cartoning systems and advanced 3D parts printing at the upcoming key ProSweets trade fair, reports Neill Barston.

The German headquartered firm from Crailsheim is set to showcase its core range of technology at the event taking placed between 30 January and 2 February 2022.

As a specialist in packaging machinery, the company has delivered a number of key innovations for the sector, and will be demonstrating a cartoning system developed for packing chocolate bars into recyclable boxes live on site.

Furthermore, Schubert Additive Solutions will be premiering its new, specially developed 3D printer for the high-quality printing of format and spare parts – the Partbox.

Schubert’s top-loading machines can perform all the tasks that are required for the fully automatic packaging of chocolate bars, chocolates, biscuits, cakes, crackers, crisps and many other products – with a high degree of flexibility and efficiency.

The company has recently returned to trade fair activity, having been among a number of other businesses represented at Gulfood Manufacturing earlier this month in Dubai, demonstrating its robotics capabilities to customers in the UAE.

As Confectionery Production examined with the company’s UK division, the company has continued to improve its market share amid the pandemic, underlined by strong sales of equipment within Britain and its wider global operations.

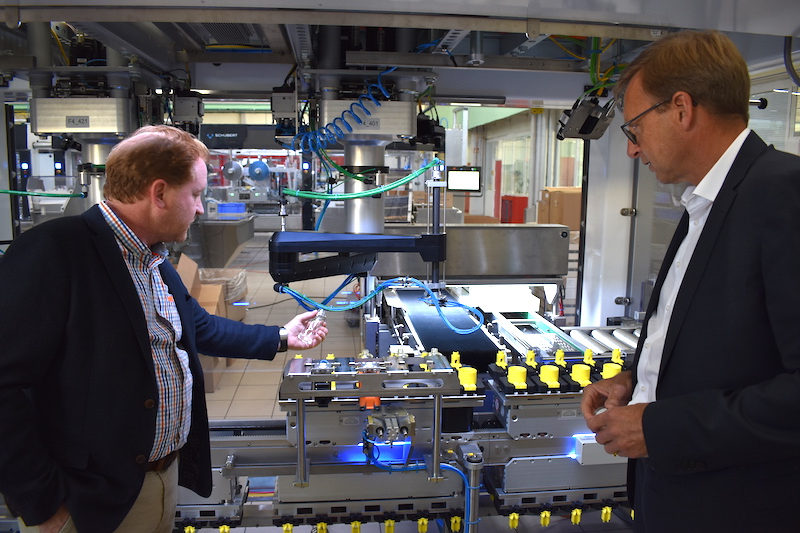

Division MD Mark Stepney (pictured left with sales director Marcel Kiessling showcasing packaging lines at its German HQ), revealed that the past year had been a notably strong one for the company, as it continued to respond to demand for innovative equipment targeting the confectionery and snacks market segments.

As the company added on its ProSweets presence, visitors will have an opportunity to experience a TLM machine in action, with its cartoning proving a focal point packing chocolate bars into boxes on site.

The customer machine will demonstrate how smaller multipacks can be packed using cardboard instead of film packaging. Thanks to pick & place robots and 3D scanners, the sweet treats will be placed into the boxes in the desired orientation.

Another key innovation on show will be its Schubert Additive Solutions’ virtual web platform, which already enables manufacturers to produce plastic parts at their own production facilities using 3D printing.

Taking this a step forward, the Schubert subsidiary has developed a high-quality 3D printer for this purpose, which is directly connected to the platform via LTE and which ensures optimum printing results.

“The Partbox is, in fact, the smallest production hall in the world and enables users to manufacture required parts directly on site. No delivery times, no warehousing – just click & print,” says Marcus Schindler, Head of Supply Chain Management and Managing Director of Schubert Additive Solutions.

The company will be taking its place at ProSweets at stand F030/G031.