GEA unveils latest packaging line for powders and granulates, targeting low-volume operations

GEA Headquarters Düsseldorf, GEA Konzernzentrale Düsseldorf

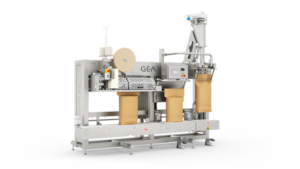

The German-headquartered GEA systems and equipment group has unveiled a new packaging line targeting product lines including confectionery, snacks, and dairy ranges, designed for low-capacity applications, writes Neill Barston.

As the business explains, its new SmartFil M1 has been developed with fine powders, and granulates in mind, with both categories being typically used within the sweets and snacks sectors around the world.

According to GEA, it believes its latest machine line (pictured below) will especially benefit companies operating in emerging markets, as well as low volume producers and pilot plants that need such a system, offering a compact and flexible low rate packing process to meet specific requirements Likewise, with their diverse portfolios, raw material producers need to be able to adapt their packaging solution in a versatile way.

With more than 100 possible variants, the GEA SmartFil M1 can be configured to suit almost any application from dry, fine powders through to coarse granular products. The new machine offers a nominal filling capacity of 120 bags per hour or three tons per hour at 25 kg product size. Depending on the product being packaged, the packaging system features configurable product metering options, including vertical auger and horizontal vibratory feeder. An optional deaeration probe may be added for improved consolidation of the product if required.

Customers can choose to pack into open-mouth bags, boxes or drums of varying sizes. Closing is configurable dependent on packaging type. Continuous heat sealing with glue reactivation or with sewing is available for open-mouth bags, whilst impulse sealing is offered for hermetic sealing of plastic packaging. The built-in height adjustable conveyor system makes packaging changes fast and simple, whilst allowing the operator to work at an ergonomic height. The integrated control panel makes it easy to reconfigure the process to activate the new functions as needed.

Powdered food ingredients that require a carefully controlled auger metering system will benefit from this option on the GEA SmartFil M1. The vertical auger design with integrated shutoff is well proven technology that is adapted from other filling systems in the GEA range. With an optional integrated deaeration probe, this filling system will enable food ingredients manufacturers to safely and reliably fill powdered products into bags, boxes or drums. With a continuous heat-sealing configuration, the SmartFil M1 can consistently produce finished products into 25kg open-mouth bags with either glued closure or sewn closure if required. Alternatively, the impulse sealing option is ideally matched with plastic bags that are commonly used with boxes or cartons.

For dairy operations, the machine can be applied for smaller scale dairy plants requiring a hygienic powder filling solution in a compact form can select the GEA SmartFil M1 with auger feed, deaeration (option) and continuous heatsealer with integrated fold-over. This is a cost effective, high quality solution for their powder packing operation. When integrated with a downline bag handling system, this cost-effective semiautomatic solution provides high quality, accurate filling and closing of open-mouth, multi-wall bags. For aluminum foil bags, the sealing system can be changed to an impulse type sealer as required.

Furthermore, the GEA SmartFil M1 is certified to current hygiene standards. GEA integrated technology elements, which secure product safety focused on special areas of the process. Being a semi-automatic operation, it is important that the filling system is easily accessible for cleaning. This was part of the design concept. Low height, accessible components make maintenance and cleaning operations easier, thereby minimising potential machine downtime and lost production.