Loesch confirms latest confectionery equipment set for ProSweets

Confectionery packaging systems manufacturer Loesch is set to unveil key equipment upgrades alongside sister firm Hastamat at the 2019 ProSweets event in Cologne next month.

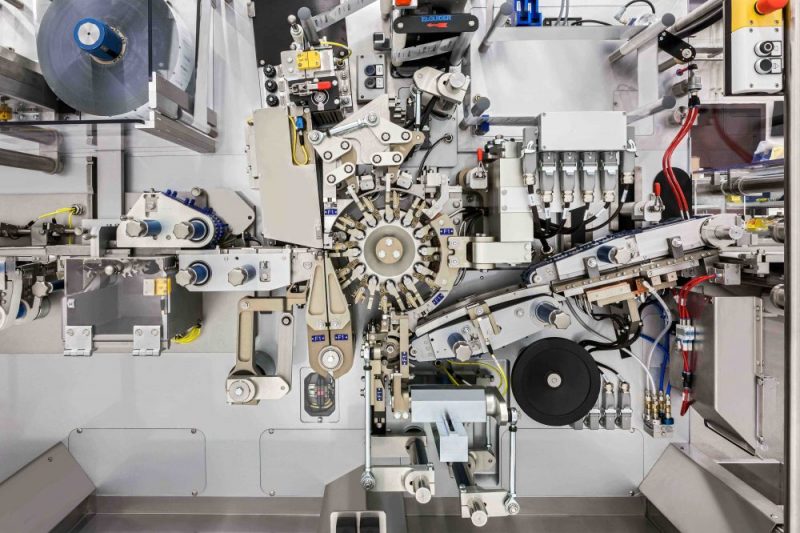

The company will be presenting its RCB-HS wrapping head machine used to produce hermetically sealed bars of chocolate. In addition to small chocolate items, the latest version of the LTM-DUO die-fold machine also reflects the growing popularity of tightly sealed chocolate bars.

According to the German-based business, hygienic product protection and a premium look for high-quality chocolate are regarded as just as important as efficient and flexible production and packaging.

Having the right equipment is therefore a top priority for any chocolate producer. These requirements are perfectly fulfilled by the packaging machinery specialists from Loesch in the latest update of the RCB-HS.

“The R series for small chocolate products and bars combines a premium look and ideal product protection in an end-to-end hermetically sealed pack,” says Loesch CEO Dr. Thomas Cord. “The extremely compact RCB-HS machine platform has been rigorously designed for top performance and handles the primary packaging in modern chocolate production reliably and flexibly.”

Since the prototype was presented, the innovative concept has undergone continuous development to the point of market maturity.

“Since its successful launch, the platform has rapidly established itself in the market, and the concept has met with a particularly enthusiastic response in markets where climate conditions demand hermetically sealed packaging,” says Cord.

The company’s RCB-HS operates continuously and produces the fold wrap in one wrapping head. It circumferentially heat-seals or cold-seals the packaging material as required. The sealing jaws always seal film against film, ensuring extremely tight packaging and preventing thermal damage to the products. For an optimum look, sealing jaws carefully affix the sealed film areas to the underside of the packaging in the discharge area.

The decision fully to dispense with hot-setting glue minimises machine soiling, reduces operating costs, and greatly simplifies operation itself. The RCB-HS uses just one hot or cold-sealable packaging material, helping to reduce costs and resources. With the help of modern film printing technology, the packaging can also be designed for a premium appearance.