Ishida launches highspeed snacks bagmaker

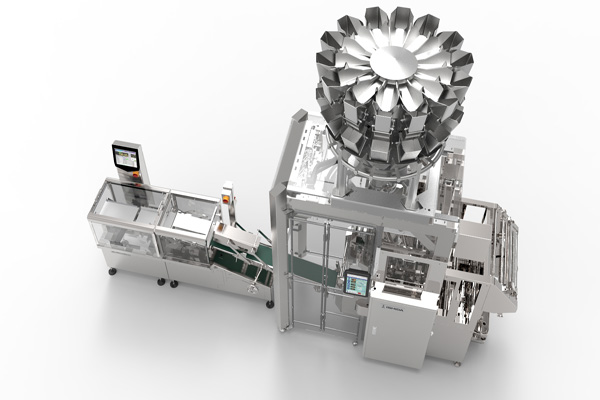

Ishida has launched a snacks bagmaker which the company says is the world’s fastest vertical form, fill and seal (VFFS) bagmaker with sustainability benefits.

The new Inspira machine delivers reduced environmental impact and improved operator working conditions, the company says. It is also intended to facilitate high levels of productivity performance, system efficiency and pack quality.

It is available in both intermittent and rotary motion versions, with production speeds of 120 bags per minute for the intermittent version and in excess of 200 bags per minute for the rotary version. At the same time, it is able to deliver an Overall Equipment Effectiveness (OEE) in excess of 99%.

Features include automated centring and tension adjustment of the film, auto-splice film management and new automated air-fill technology which optimises pack thickness for downstream automated case packing. By shortening the path of the film from printer to sealing jaw, Ishida says the new design also helps to further reduce film waste, the company says.

The new models are intended to offer a wider choice of bag sizes with the minimum bag width reduced to 50mm, along with a wider choice of film reel weights, up to a maximum of 50kg.

A 15.3-inch touchscreen provides a HMI (Human-Machine Interface) as part of an enhanced ‘visual management’ strategy designed to improve operator productivity. Ishida says that this ensures ease of set-up with various automatic adjustment functions, such as positioning of the printer, former roller adjustment, N2 gas flow management and film roll centring, synchronised with the relevant product recipe settings to eliminate operator errors.

The Inspira also features an open construction for product changeovers and maintenance. The 304-stainless steel construction is intended to minimise the risk of corrosion which can be caused by a combination of constant exposure to seasoning and cleaning regimes.

The bagmaker also incorporates the latest technologies to reduce energy and air consumption for an improved environmental profile, Ishida says. In the intermittent motion model, power consumption has been reduced by 24.8% in standby mode and by 16.8% during operation.

The Inspira forms part of Ishida’s iTPS (integrated Total Packing System) which supports integrated operation with Ishida multihead weighers, throat metal detectors, printers, sealtesters, checkweighers and case packers.