The heat is rising

It is the accurate control of temperature across multiple steps in the production of chocolate that ensures the quality of the final product. For this reason, modern temperature controllers have a vital role to play, Ian Collins explains.

The temperature susceptibility of chocolate plays a huge role in its surprisingly complicated manufacturing process. From the initial cocoa bean roasting and winnowing, through grinding, conching and tempering and onto moulding, every step of the chocolate manufacturing process must be temperature controlled to extremely tight tolerances. This is not only to bring out the taste of the product, but also to create the best possible appearance and mouthfeel.

Chocolate was introduced to Europe by New World explorers in the sixteenth century, but manufacturing processes used by chocolatiers are now broadly the same around the world, with added ingredients and processing variables responsible for the differences between chocolate varieties. Each manufacturer will have their own secret processing steps, timings and ingredients, but all of them share a common bond and that is the crucial role that temperature control has on the quality, taste and feel of the final product.

Also of interest is the fact that chocolate contains antioxidants, flavanols and polyphenols; early stage processing at temperatures lower than 46°C (115°F) helps to preserve these beneficial ingredients.

Following cleaning, the roasting of the beans is the initial temperature-dependent step. The beans are typically roasted at temperatures between 100°C (212°F) and 150°C (300°F) for 20 to 40 minutes to bring out the flavour and colour of the chocolate. The type of beans used and the type of chocolate desired after final processing will determine the temperature at which the beans are roasted. This is therefore the first of many opportunities that a chocolate manufacturer has to create a unique product through temperature control.

Roasting

After winnowing, which removes the husks, the remaining cocoa nibs undergo additional processing before being roasted. The duration and temperature of the roasting are determined by nib type; there may be more than one variety present to influence the final taste and texture of the chocolate. Again, the roasting temperature must be tightly controlled. The roasted nibs are then ground and liquefied to produce chocolate liquor, which is usually pressed to extract cocoa butter, with the remaining solids being processed to create chocolate powder.

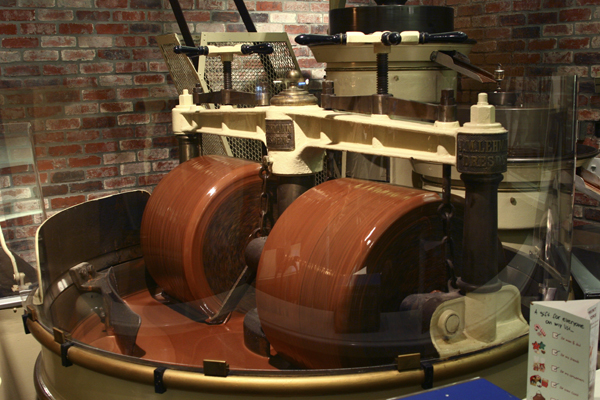

The next step, conching, is a process unique to chocolate making. It immediately follows the addition of other ingredients, such as sugar or milk, and is the single biggest contributor to the organoleptic (taste/smell) qualities of the finished product. Conching uses metal rollers or mixers to grind or knead the mixture to refine and blend it, with heat from the friction turning it into (and maintaining it in) a liquid state. This is another temperature-critical process, in which the temperature can rise as high as 80°C (176°F) for dark chocolate, but should not exceed 55°C (131°F) for milk chocolate, to avoid caramelisation. Air flowing through the conche removes unwanted acids, while moisture is also reduced and substances produced in the original roasting are oxidised, resulting in a mellower flavour.

One of the key contributors to the price of premium chocolate is the length of conching time. While four to six hours is generally considered adequate, gourmet chocolate may have been conched for up to 80 hours – significantly increasing the manufacturing cost. The resulting particle sizes are actually smaller than the distance between human taste buds, improving the mouthfeel by giving a velvety sensation on the tongue. Conching also changes the flavour distribution within the chocolate, with extended conching creating a homogeneity that gives high end chocolate its unique taste. Here, again, temperature control is critical.

Tempering

As well as a pleasant taste and mouthfeel, a shiny finish and a ‘snap’ when broken are also signs of optimum processing. These are achieved in what is perhaps the most temperature critical step in the chocolate manufacturing process – tempering. Tempering is a tightly controlled process, which sees the temperature of the chocolate gradually raised, lowered and raised again in order to form exactly the right kind of crystals. This avoids discoloration and fat blooms in the product by preventing the development of certain crystalline formations. Cocoa butter comprises several glycerides of fatty acids, which solidify at different temperatures. When the liquid chocolate is cooled, fatty acid crystals form nuclei, around which the other fatty acids crystallise – creating a single, stable form. Once that action has taken place, the temperature needs to be raised again to prevent these from solidifying.

Chocolatiers all have their own ways of doing things, using certain equipment and particular routines, but one of the biggest differentiators remains the tight control of the processing temperatures. These days it is hard to find a chocolatier who can do it by sight and feel alone, with most modern production relying on a modicum of technology to supplement the art of chocolate making. But these people are not engineers; they need something that is easy to use, reliable and accurate.

The magic of the mixed ingredients, the blending and the timing can be left to the experts with their years of experience, while the relatively straightforward temperature control aspects can be trusted to temperature controllers. Simple applications require relatively simple instrumentation.

So, next time you bite into a chocolate bar from the corner shop or a premium truffle from a boutique, just remember the steps the manufacturer has taken to ensure you get that familiar feel and taste and – just as importantly – how accurate temperature control was instrumental in achieving that texture and flavour.

Author

Ian Collins is product and marketing manager at West Control Solutions, which specialises in process and temperature control for industries such as food, beverage and packaging.