Exclusive: Kruger and Salecker set to deliver new gummy production line for Interpack

pic: Soren Bettex of Kruger & Salecker at the World Confectionery Conference. Pic: Cedric Puisney

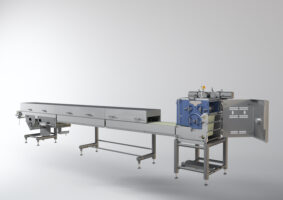

Germany’s Kruger & Salecker equipment group has unveiled its advanced FFW gummy production line – capable of forming items rapidly within just 12 seconds, according to the company, writes Neill Barston.

Moreover, the manufacturer is planning to offer a broad overview of its equipment portfolio, which is spread over three main areas – moulding machinery lines for pastes, proteins and marzipan, a second strand of machinery for pourable ingredients, as well as its all-new invention targeting the gummy and jellies segment, which it believes has particular potential within the fast-rising nutraceutical category.

Speaking to Confectionery Production, general director of sales, Soren Bettex, which last year played a key role in our World Confectionery Conference (pictured main image), welcomed its prospects for the event. He said: “For me, this will be my first Interpack, and I’m really excited, as we’re get- ting the feedback from the market is going to be there. So, we’re really looking forward showing our new market approach that we have developed for the company since we took over the business.

“We’ll be showing some new innovations, as well as financing models, so for us it’s going to be a really exciting event,” he noted, expressing confidence that wider market conditions were starting to improve notably in relation to Covid-19, as well as the broader impact from the ongoing war in Ukraine also showing signs of a diminishing impact in terms of its destabilisation of the energy sector and food supply chains.

As Soren observed, he was glad of the chance to showcase the business at our World Confectionery Conference in Brussels last September, in which he offered a technical presentation on the company’s ever-expanding capabilities.

He revealed there had been considerable research and development that has gone into devising the new FFW line – which employs a markedly different approach to many other conventional systems, which will be displayed at Interpack, being staged between 4-10 in Dusseldorf, Germany (at Hall 3, stand F96).

According to the senior director, its latest series, will be launched to a standard working width of 400mm, offering output capability of between 250 to 400 kg/hr. As its development team confirms, the design of the system, which is being fully patented, has few moving parts, making cleanability levels high. This also means that the risk of cross contamination can also be kept to a minimum in terms of hygiene management.

Reflecting on his own pathway in the industry, he acknowledged that he is a relative newcomer into the sector, but with his own passion for industrial processes being born of a background as an automotive mechanic in his youth, he added that developing business strategy has been a long-term focus, and he believed that Kruger & Salecker has made key strides during the past few years.

“My cousin had been the chief operating officer at the business for the previous eight years before we took over three years – so we teamed up and that’s where we started from. From my background, I am excited about complex systems and looking at how to scale things and new ventures forward. Of course, we didn’t plan on the pandemic happening just as we were getting going just before the first big lockdowns, but that was then, and now we’re getting some very good market feedback for the business.”