Special focus: Forming and extrusion market challenges

The BCH stand at this year's ProSweets event. Pic: Neill Barston

Extrusion processes for confectionery have become ever more elaborate over the years, with consumers demanding a greater array of sweets and snacks options. Confectionery Production explores recent sector developments. Neill Barston reports

As we’ve previously noted, extrusion remains an especially vital process within the confectionery sector, though it’s a technical area requiring particular dedication in machinery development. Its strength lies in being able to produce sweets ranges in rapid fashion, with changeovers to additional items frequently being a prominent feature of such operations.

Significantly, it remains a sizeable market, put at $45.42 billion in 2020, with studies from Research and Markets forecasting growth globally of up to five per cent over the next few years. Notably, the report discusses the advantages of extruder technology, such as the ability to choose the ingredients and the ways of processing them to produce healthier snacks with varied ingredients and diverse taste, texture and visual appeal.

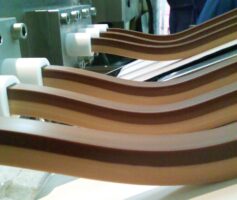

For its part, British-based business BCH has gained a strong specialism in extrusion work, engaging with a number of manufacturers around the world in supplying its well-established ranges.

This includes having supplied Danish liquorice business Lakrids by Bülow, which has expanded significantly over the past decade with the assistance of a sole extrusion line from the Lancashire business. Stuart Grogan, operations manager for BCH (pictured at ProSweets 2022), says: “We are very proud that our solution has helped Lakrids grow and become the internationality renowned brand that it is today for such a fantastic range of high quality products. It’s always nice to see our machines performing in many of the marketing videos and photos that Lakrids put out

too,” he noted of the company’s rise.

Another business keeping ahead of the pace of market change is Clextral, which has used its twin screw extruder systems to strong effect.

Speaking to Confectionery Production recently, Julie Prost, pilot plant manager and process engineer noted the numerous diets emerging, the most significant being keto and paleo where sustainability and ethical production are also driving these choices. With these diets on the rise, suppliers must answer the needs of grain-free, gluten-free, GMO free, vegan and allergen-free trends, adding to the challenges of ingredient selection.

For its part French-based Proform has also enjoyed success within this market segment, with one of its clients, Kenya’s Mzuri Sweets, noting key market breakthroughs using the European firm’s equipment. Ashish Shah, head of Mzuri Sweets, said: “We are the largest producer of high quality confectionery in our country. We have several Proform Extrusion and forming Lines, the first one was bought in 2008 and is still producing Kenya’s number one bubblegum ‘Gomba’. After experiencing the great results of this first investment, we planned and acquired various other extrusion lines from the company. “Among our various other projects executed with Proform equipment, are gumball forming lines, several cut and wrap extrusion lines, centre-filling extruders and Africa’s first Intruder line for producing high quality toffees and chews. “We are extremely happy with the performance and support from the Proform equipment and team and we very eagerly look forward to the completion of our next big project.”

As a business, the French company has been designing and building machinery for over 25 years, and explained that determining the extruder or other forming equipment is a careful process, beginning with the specification of the product itself. General manager, Christian Gand, enthuses: “If we know that our client has chosen for example a cut and wrap machine working in a range from 800 to 1800 pieces/minute, with the finished dimensions and weight of one-piece, we will work from there, to determine the extrusion and forming line, from the type of extruder, to the residence time of the cooling tunnel to rope calibrating and speed balancing into the client’s wrapping machine, ensuring it can run optimally and at top speed.”

He continues: “Our clients expect our extruders to run to exact specification, reliably and throughout the production run; a quality product at extruder output is the first step in controlling the result after forming and wrapping. “Our clients are also looking for flexibility; using the same extruder for both chewing gum and chewy candy, to reduce initial expense and invest progressively in further production and forming lines. Or the flexibility offered by a continuous Mixing Extruder, either to continuously mix & extrude bubble or chewing gum, a superior result with no operator handling or using the Mixer Extruder to continuously colour & flavour neutral gum, as change-overs are very quick. This is also a solution for manufacturers who want to make several colours or flavours simultaneously.

Prosweets success

Elsewhere, Germany’s Hebenstreit, a global manufacturer of wafer production lines for flat and hollow wafers, as well as state of the art snack extrusion lines has also specialised in extrusion.

The company supplies single screw snack extrusion lines for various product shapes, as well as process equipment for mixing and feeding of the ingredients.

Its SE snack extruder series is the only one combining the Turbo technology with the direct drive system which provides substantial advantages to the user. The trends in the snack extrusion are nowadays products with healthier ingredients. The raw material can vary from corn to rice, peas, soya and many others.

Recently at ProSweets in Cologne, the firm presented its wafer baking technology where the wafer sheet size can be up to 1000 x 350mm. In addition, it also showcased its state of the art snack extruder SE 70 which also includes the well known “Turbo” and direct drive technology.

Also active in the segment, equipment and systems business GEA has recently unveiled its xTru Twin series of high-capacity extruders lines for industries including

confectionery and snacks, with a new flagship version.

The new range-topping model, known as the 140, has been developed with advanced features, including powered screws providing users up to a reported 40 per cent increased capacity with the same efficiency, quality and footprint as previous versions of the series.

Furthermore, this high-capacity technology has also been designed to be applied to the other models of the GEA xTru Twin extruders too – models 70/92/112 – and retrofitted to older machines to increase their capacity without changing the floorplan of the factory.

The GEA xTru Twin extruders (left) offer the flexibility to produce a wide range of products including: cereal-based snack pellets die-cut, 2D, 3D, multilayers, square shape, punched and direct expanded; including breakfast cereals; crisps and other series of food products. The latest xTru Twin 140 has a production capacity of over three tons of pellets. A further manufacturer that has made strides in recent times is Netherlands-based Extrufood.

The company recently told Confectionery Production that it had been in a strong position to respond to the current global commercial upturn within sweets markets.

Consequently, it noted that the past year has seen the business being notably active, amid a wider growth in comfort food.

The company supplies custom made production lines from 20 kg/hr to up to 2.000 kg/hr, which ensures almost limitless possibilities of confectionery products. The production lines create an exciting variety with up to eight different colours and flavours, with various fillings and coatings, that has enabled the business to offer distinctive solutions in a particularly competitive market.