Ishida weighing systems target confectionery market

A new high capacity 10 and 14 multihead weighing system devised for confectionery has been unveiled by Ishida Europe.

The company’s latest release targets items such as wafers, biscuits and frozen items that are considered to be more fragile than standard ranges.

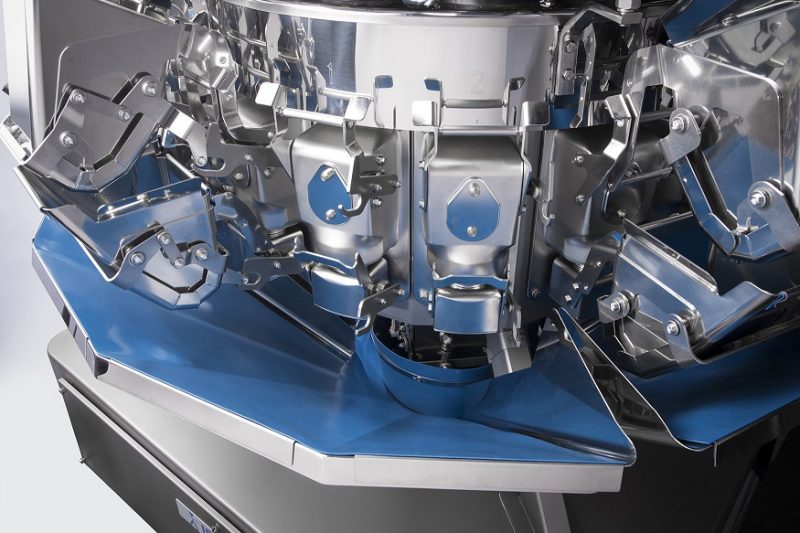

As the business revealed, easily-breakable products can pose a challenge for automated weighing systems. In response, the design of the new Ishida CCW-RV weighers incorporates gentle slopes and reduced angles throughout the weigher to ease the passage of the products.

Bancollan inserts for the hoppers and discharge chute provide effective cushioning, while unique curved pool and weigh hopper designs deliver controlled deceleration further minimising the potential for breakages.

In addition, a ring shutter helps prevent breakages due to product collisions in the discharge chute during transfer of product into the packaging machine.

For fragile frozen products such as pasta, seafood, fruits, vegetables and bakery items, the GS model can be specified in a WP waterproof version which provides industry leading protection for the weigher in more challenging factory environments.

The IP69K test rating means that the weigher offers the highest levels of water and dust resistance, making it perfectly suited to applications where equipment has to be thoroughly sanitised.

The CCW-RV 10 and 14 heads GS offer all the proven benefits of the Ishida RV range with its reputation for unsurpassed accuracy and efficiency.

According to the company, all heads are capable of being used in a single combination calculation, and the unique triple combination calculation software can calculate three optimal weight combinations, double checks them and then select the one nearest to the target weight, all in a single cycle.

This minimises error discharges and increases efficiency, while also enhancing weighing accuracy and consistency. Anti-floor vibration removes background vibration from the load cell output signal, improving signal stability and machine accuracy.

Speeds of up to 65 per minute for the 10 head and 90 packs per minute for the 14 head model can be achieved, depending on product characteristics and required target weight.