Dessert producer expands

An RF2 offline sleeve coding system from Rotech has given Pots & Co a flexible coding solution – enabling the rapidly growing artisan dessert producer to take on and fulfil major retail contracts while minimising capital outlay.

Pots & Co produces a retail range of high end desserts from recipes developed by Michelin-trained chefs. The desserts, which are handmade and packed in individual ceramic ramekins with plastic lids and an outer cardboard sleeve, include lemon and lime posset, chocolate and orange pot and sticky toffee pudding.

The boutique company has grown exponentially since it was founded by Julian Dyer in 2010. In 2012 Pots & Co was making about 1,500 desserts a week, supplied to Selfridges and a handful of Waitrose stores. By the end of 2013, it was producing more than 10,000 pots per week by hand. Now, this figure has risen to 60,000 desserts per week, destined for 500 Tesco stores, 300 Waitrose stores and other top tier retailers such as Booths and Selfridges.

As the company has grown its coding requirements have changed. In the early days, hand stamping 2,000 sleeves a day with use by dates was perfectly manageable. However, when four figures became five in a very short space of time, Pots & Co knew it needed a faster method.

A‘Google’ search of coding equipment suppliers threw up several companies, among them Hertfordshire-based packaging coding and marking specialist Rotech.

Rotech visited Pots & Co’s London factory and carried out trials on its sleeves. This instilled confidence in Pots & Co operations director Fraser Thomson that Rotech could handle its intricately shaped sleeves.

“What we liked about Rotech is that they didn’t just give us list of machines and a list of prices. We felt they had more expertise than the other coding companies we saw and that made us confident that they would adjust the coder to suit our sleeves rather than simply selling us a standard machine. They were also very much of the attitude that they would sort out any problems or challenges we might have,” he says.

As the dessert production process is completely manual, Pots & Co wanted an offline coder – but it also wanted a fast coder.

“We produce between 10,000 and 12,000 desserts a day, five days week, depending on what offers we have on with Tesco or Waitrose. We needed a coder that could keep pace with those volumes,” says Fraser.

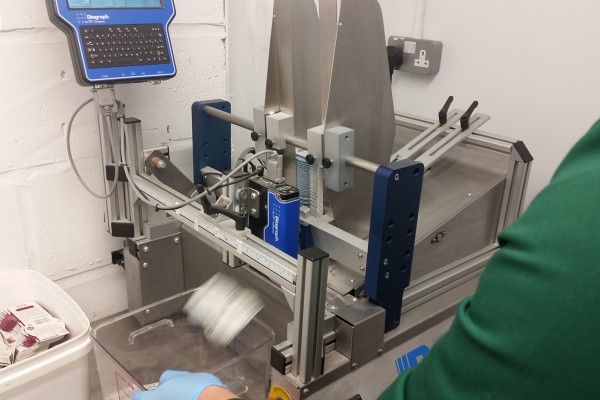

Rotech recommended its RF2 – a standalone friction feed overprinting system that would enable Pots & Co to code sleeves offline and bring them to the production line already printed. Engineered specifically for the food industry, the RF2 uses Rotech’s stack-to-stack feeding technology to pick sleeves from a stack, accurately print date or batch codes, and place the printed sleeve neatly onto another stack for collection, all at speeds of 400 per minute.